Moisture control is critical in industries such as pharmaceuticals, electronics, food packaging, aerospace, and logistics. When humidity levels rise, products can degrade, corrode, or lose structural integrity—resulting in costly damage. That’s where desiccants silica gel plays a vital role. Among the most widely used desiccants are indicating silica gels, which change color as they absorb moisture.

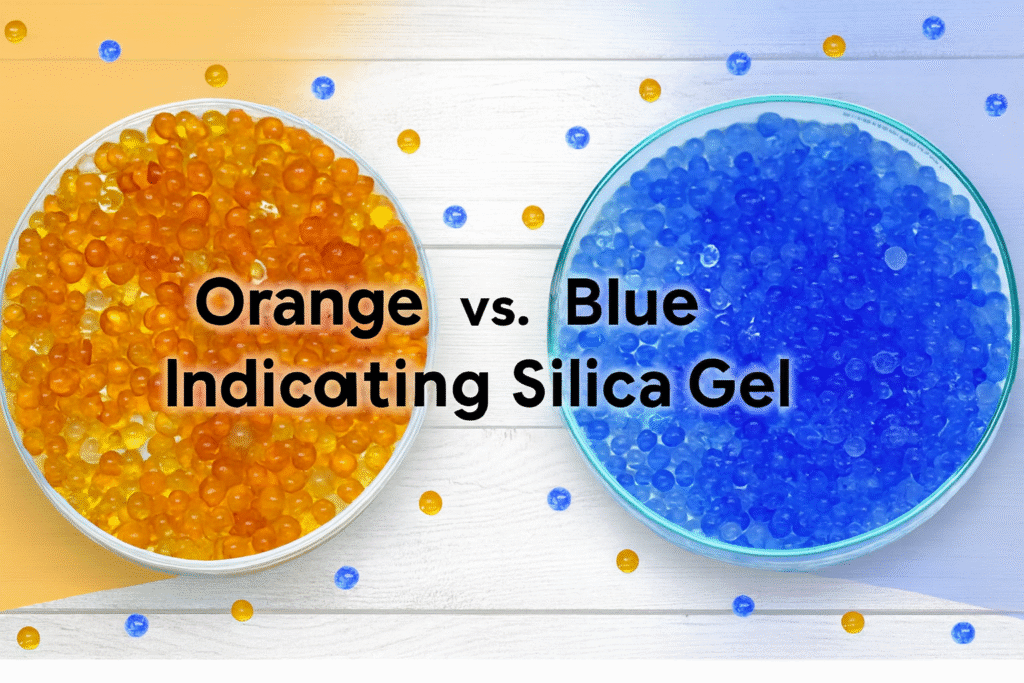

Two of the most common types are orange indicating silica gel and blue indicating silica gel, each designed with different moisture-indicating agents, applications, and safety profiles. While both serve the same purpose—adsorbing moisture—their compositions, environmental considerations, and usability vary significantly.

In this comprehensive guide, we break down the differences between silica gel blue and silica gel orange, explore how silica gel orange to green color transitions work, and help you determine which type is ideal for your application.

What Is Indicating Silica Gel?

Indicating silica gel is a type of moisture-adsorbing desiccant that changes color based on the level of saturation. Unlike standard silica gel beads, which remain the same color regardless of humidity, these beads provide a visual cue that shows when they are dry or have reached their moisture capacity.

This visual indicator makes them ideal for:

- Sensitive electronics

- Optical instruments

- Laboratory equipment

- Product packaging

- Storage containers

- Industrial machinery

The indicator eliminates guesswork and ensures timely replacement or regeneration, making moisture control more efficient and predictable.

Understanding Blue Indicating Silica Gel

Blue indicating silica gel is one of the oldest and most widely recognized moisture-indicating desiccants. In its dry state, it is deep blue. As it absorbs moisture, the beads gradually turn pink. The color shift is caused by the presence of cobalt chloride, a moisture-sensitive chemical indicator.

How Blue Indicating Silica Gel Works

- Dry state: Rich blue

- Partially saturated: Light blue

- Fully saturated: Pink

Cobalt chloride reacts with absorbed water molecules, causing the color transition. The stronger the moisture content, the lighter the blue until it reaches a noticeable pink shade.

Benefits of Silica Gel Blue

- Strong visual contrast

The change from blue → pink is highly noticeable. - High adsorption capacity

It performs exceptionally well in environments with rapidly fluctuating humidity. - Ideal for industrial applications

Especially in enclosed systems that demand precise humidity monitoring.

Limitations of Blue Indicating Silica Gel

The primary concern is the presence of cobalt chloride, classified by the EU as a hazardous substance. This has led to regulatory restrictions in many countries.

- Not permitted in food-related packaging in several markets

- Restricted in the EU under chemical safety guidelines

- Requires careful handling and disposal

Because of this, many industries are switching to safer alternatives like silica gel orange.

What Is Orange Indicating Silica Gel?

Orange indicating silica gel is a safer, non-toxic alternative developed to replace cobalt chloride-based blue variants. When dry, the beads appear bright orange. As they absorb moisture, they transition through yellow and ultimately to a greenish shade—known as silica gel orange to green.

How Silica Gel Orange Works

- Dry: Bright orange

- Medium saturation: Yellow

- Fully saturated: Green

The moisture-indicating agent in this type of silica gel is methyl violet, which is significantly safer for both industrial environments and consumer-facing products.

Benefits of Orange Indicating Silica Gel

- Non-toxic and environmentally friendly

Complies with global safety standards including REACH. - Wider application versatility

Safe for food packaging, pharmaceuticals, and personal goods. - Clear indication

The orange → yellow → green change is easy to interpret. - Growing industry preference

Due to the increasing focus on eco-friendly desiccant solutions.

Limitations of Silica Gel Orange

While it is safer, some users prefer the sharper visual contrast of blue → pink found in silica gel blue. Additionally, in very dark or low-visibility environments, orange/yellow/green shifts may require closer inspection.

Chemical Composition: The Key Difference

| Feature | Silica Gel Blue | Silica Gel Orange |

|---|---|---|

| Indicator Chemical | Cobalt Chloride | Methyl Violet |

| Safety Classification | Hazardous / toxic | Non-toxic |

| Regulatory Status | Restricted in EU & food applications | Globally accepted |

| Color Change | Blue → Pink | Orange → Yellow → Green |

| Environmental Impact | Potentially harmful | Eco-friendly |

The presence of cobalt chloride explains why blue indicating silica gel is slowly being phased out in many industries, while orange indicating silica gel is becoming increasingly popular.

Performance Comparison: Which Works Better?

Both types perform well in desiccation, but their strengths differ depending on the use case.

Moisture Adsorption Capacity

Both have similar adsorption capacities since the base material—amorphous silica gel—is the same. The main difference is in how clearly they show saturation.

Visibility and Color Contrast

- Blue → pink is extremely noticeable

- Orange → green is less dramatic but still clear

Safety and Compliance

Here, orange gel wins clearly.

- Silica gel blue must be labeled as hazardous

- Silica gel orange is REACH-compliant and widely accepted globally

Regeneration

Both types can be regenerated by heating at 110–120°C for 1–2 hours until they return to their dry state.

However, repeated regeneration may lighten the indicator color over time.

Applications of Orange and Blue Indicating Silica Gel

Where Silica Gel Blue Is Commonly Used

Despite safety restrictions, silica gel blue remains in demand in industrial environments where direct consumer exposure is limited, such as:

- Transformers and switchgear equipment

- Industrial air dryers

- Machine enclosures

- Optical storage devices

- Enclosed instrumentation cases

- High-capacitance moisture removal systems

Where Silica Gel Orange Is the Preferred Choice

Because it is safe and non-toxic, silica gel orange is increasingly used in:

- Pharmaceutical packaging

- Food grade applications

- Consumer products like shoe boxes and electronics

- Museums and archival storage

- Leather goods storage

- Household humidity control devices

The silica gel orange to green color change provides reliable saturation detection without safety concerns.

Why Color Indication Matters

Visual indication is one of the biggest advantages of using indicating desiccants silica gel. A simple color shift gives real-time feedback on moisture exposure, helping users make quick and informed decisions. Here’s why the color cue is so important:

-

Prevents Damage Before It Happens

The color change acts as an early-warning system. Instead of waiting for equipment to show signs of moisture damage, corrosion, or product spoilage, users can instantly detect rising humidity simply by checking whether the blue indicating silica gel or orange indicating silica gel has shifted in color. This reduces the risk of costly failures in electronics, pharmaceuticals, optical devices, and sensitive packaging.

-

Ensures Reliable Protection

Indicating gels remove the guesswork from moisture control. When the color fully transitions—such as silica gel orange to green—it clearly signals that the desiccant has reached saturation. This makes maintenance more reliable because users know exactly when to replace or regenerate the material. It improves quality control and helps maintain consistent product integrity during storage or shipping.

-

Reduces Operational Downtime

Moisture buildup inside industrial systems can stop production, trigger electrical malfunctions, or require expensive repairs. By identifying saturation early, technicians can replace the desiccant before the equipment is compromised. This keeps operations running smoothly and minimizes unplanned downtime, especially in sectors like aerospace, manufacturing, and precision engineering.

-

Increases User Safety

Color indication also plays a crucial role in safety-sensitive environments. In areas involving medical supplies or food packaging, non-toxic indicators—such as orange indicating silica gel, which is cobalt-chloride-free—offer safer moisture protection. By using non-hazardous visual cues, manufacturers meet regulatory requirements while protecting end users from exposure to harmful chemicals.

Environmental Regulations & Safety Considerations

Blue Indicating Silica Gel Restrictions

The EU Chemical Agency classifies cobalt chloride as:

- Carcinogenic

- Mutagenic

- Toxic for reproduction

Therefore, its use is restricted in:

- Consumer products

- Food packaging

- Pharmaceutical environments

Orange Indicating Silica Gel: A Safer Future

Because it’s free from harmful heavy metals, the adoption of silica gel orange is increasing rapidly, supported by global regulations favoring environmentally friendly materials.

Future Trends in Indicating Silica Gel Technology

The desiccant industry is evolving rapidly as companies strive for safer, smarter, and more sustainable solutions. Here are the most prominent trends shaping the future of indicating silica gel:

-

Eco-Friendly Desiccants Becoming the Standard

Industries worldwide are moving away from products containing cobalt chloride, the chemical responsible for the traditional blue-to-pink color change. As regulations tighten, silica gel orange is becoming the preferred choice thanks to its non-toxic properties. This shift supports both environmental sustainability and user safety.

-

Smart Desiccants

Technology is transforming even basic moisture control products. A growing trend is pairing desiccants with digital humidity sensors and wireless tracking devices. These “smart desiccants” provide real-time moisture data, location tracking, and automated alerts—ideal for high-value shipments in pharmaceuticals, defense, aerospace, and electronics.

-

Regulatory Pressures Worldwide

More countries are considering restrictions or complete bans on cobalt chloride due to health concerns. As regulations become stricter, manufacturers are rapidly transitioning to indicator systems that rely on safer alternatives like silica gel orange. This trend will accelerate global adoption of eco-friendly desiccants.

-

Enhanced Regenerative Gels

Research is pushing the boundaries of regenerative capability. New formulations are being developed to maintain color sharpness, adsorption efficiency, and structural stability even after multiple regeneration cycles. These next-generation desiccants offer longer lifespan and better performance, reducing waste and long-term costs for industries that depend on moisture control.

Conclusion: How to Choose Between Orange and Blue Indicating Silica Gel

Both silica gel blue and silica gel orange effectively reduce humidity and protect products from moisture damage. The primary difference lies in their safety profile and indicating chemicals.

Choose Silica Gel Blue If:

- You work in heavy-duty industrial environments

- Visual contrast (blue → pink) is critical

- Local regulations allow cobalt-based desiccants

- You need high-performance moisture adsorption in non-consumer applications

Choose Silica Gel Orange If:

- Safety, environmental compliance, or food-grade requirements matter

- You need a non-toxic, REACH-compliant solution

- Your product will be handled by consumers

- You want a sustainable alternative to cobalt-based gels

In most modern applications, orange indicating silica gel is the preferred choice.

Frequently Asked Questions

-

Q1. What is the difference between orange and blue indicating silica gel?

- Orange indicating silica gel uses a non-toxic indicator (methyl violet), while blue indicating silica gel uses cobalt chloride. Both absorb moisture, but orange gel is safer and more environmentally friendly.

-

Q2. Is orange silica gel safer than blue silica gel?

- Yes. Orange silica gel is non-toxic and REACH-compliant, making it suitable for food, pharmaceuticals, and consumer products. Blue silica gel contains cobalt chloride, which is classified as hazardous.

-

Q3. What does it mean when orange silica gel turns green?

- When orange silica gel turns yellow and eventually green, it indicates that the desiccant is fully saturated with moisture and needs to be replaced or regenerated.

-

Q4. Can blue indicating silica gel be used in food packaging?

- No. Blue silica gel is generally restricted in food packaging due to the presence of cobalt chloride, which is considered harmful.

-

Q5. How long does indicating silica gel last?

- Indicating silica gel can last months to years depending on humidity levels. It can also be regenerated multiple times by heating it at 110–120°C for 1–2 hours.

-

Q6. Which silica gel is better for electronics storage?

- Both work well for electronics, but orange silica gel is preferred due to its non-toxic nature and compliance with global safety standards.

-

Q7. How to regenerate indicating silica gel at home?

- Spread the beads evenly on a baking tray and heat them in an oven at 110–120°C for 1–2 hours until they return to their original dry color.

-

Q8. How to know when silica gel needs replacement?

- Check the indicator color. Blue silica gel turns pink when saturated. Orange silica gel changes from orange → yellow → green, indicating it has absorbed maximum moisture.

-

Q9. How to choose the right silica gel for your application?

- Choose blue silica gel for industrial, enclosed systems and orange silica gel for food, pharma, consumer goods, and eco-friendly applications.

-

Q10. How to store silica gel for longer life?

- Store silica gel in airtight containers away from high humidity. Exposure to open air can cause premature saturation.

-

Q11. How to dispose of silica gel safely?

- Orange silica gel is non-hazardous and can be disposed of normally. Blue silica gel must follow hazardous waste guidelines depending on local regulations.

-

Q12. How to use silica gel packets effectively in packaging?

- Place the packets inside sealed containers or packaging, ensuring they are not exposed to open air. Choose packet size based on product volume and humidity sensitivity.